Pipe Fitting Losses

Head loss in a pipe is sum of following -

- Elevation difference, hZ

- Fitting losses, hL

- Friction losses, hF

Fitting losses hL is calculated as

hL = K(V²/2g)where, K is resistance coefficient due to fittings, V is fluid velocity and g is acceleration due to gravity.

Friction losses hF is calculated as

hF = f(L/D)(V²/2g)where, f is Darcy's pipe friction factor, L is pipe length and D is pipe inside diameter.

Total head loss in a pipe -

hTotal = hZ + hL + hFPressure drop due to head loss in pipe is calculated as

ΔP = hTotal.ρ.gwhere, ρ is fluid density.

There are several methods for estimating pipe fitting losses like equivalent length method, K method, 2-K (Hooper) method and 3-K (Darby) method. 3-K method is most accurate followed by 2-K method.

2-K (Hooper) Method

K = K1/Re + K∞ (1 + 1/ID )where, Re is Reynold's number, K1, K∞ are constants and ID is inside diameter in inches.

3-K (Darby) Method

K = K1/Re + K∞ (1 + Kd/Dn0.3 )where, K1, K∞, Kd are constants and Dn is nominal pipe diameter in inches.

Constants for 3K and 2K method for some common fittings.

| 90° Elbow | K1 | K∞ | Kd |

|---|---|---|---|

| Threaded, r/D = 1 | 800 | 0.14 | 4.0 |

| Threaded, Long Radius, r/D = 1.5 | 800 | 0.071 | 4.2 |

| Flanged, Welded, Bend, r/D = 1 | 800 | 0.091 | 4.0 |

| Flanged, Welded, Bend, r/D = 2 | 800 | 0.056 | 3.9 |

| Flanged, Welded, Bend, r/D = 4 | 800 | 0.066 | 3.9 |

| Flanged, Welded, Bend, r/D = 6 | 800 | 0.075 | 4.2 |

| Mitered, 1 Weld, 90° | 1000 | 0.270 | 4.0 |

| Mitered, 2 Weld, 45° | 800 | 0.068 | 4.1 |

| Mitered, 3 Weld, 30° | 800 | 0.035 | 4.2 |

| 2K Method | |||

| Mitered, 4 Weld, 22.5° | 800 | 0.27 | |

| Mitered, 5 Weld, 18° | 800 | 0.25 | |

| 45° Elbow | K1 | K∞ | Kd |

|---|---|---|---|

| Standard, r/D = 1 | 500 | 0.071 | 4.2 |

| Long Radius, r/D = 1.5 | 500 | 0.052 | 4.0 |

| Mitered, 1 Weld, 45° | 500 | 0.086 | 4.0 |

| Mitered, 2 Weld, 22.5° | 500 | 0.052 | 4.0 |

| 180° Bend | K1 | K∞ | Kd |

|---|---|---|---|

| Threaded, r/D = 1 | 1000 | 0.230 | 4.0 |

| Flanged/ Welded, r/D = 1 | 1000 | 0.120 | 4.0 |

| Long Radius, r/D = 1.5 | 1000 | 0.100 | 4.0 |

| Tees | K1 | K∞ | Kd |

|---|---|---|---|

| Standard, Threaded, r/D = 1 | 500 | 0.274 | 4.0 |

| Long Radius, Threaded, r/D = 1.5 | 800 | 0.140 | 4.0 |

| Standard, Flanged/ Welded, r/D = 1 | 800 | 0.280 | 4.0 |

| Stub-in Branch | 1000 | 0.340 | 4.0 |

| Run Through, Threaded, r/D = 1 | 200 | 0.091 | 4.0 |

| Run Through, Flanged/ Welded, r/D = 1 | 150 | 0.050 | 4.0 |

| Run Through Stub in Branch | 100 | 0 | 0 |

| Valves | K1 | K∞ | Kd |

|---|---|---|---|

| Angle Valve = 45°, β = 1 | 950 | 0.250 | 4.0 |

| Angle Valve = 90°, β = 1 | 1000 | 0.690 | 4.0 |

| Globe Valve, β = 1 | 1500 | 1.700 | 3.6 |

| Plug Valve, Branch Flow | 500 | 0.410 | 4.0 |

| Plug Valve, Straight Through | 300 | 0.084 | 3.9 |

| Plug Valve, 3-way, Flow Through | 300 | 0.140 | 4.0 |

| Gate Valve, β = 1 | 300 | 0.037 | 3.9 |

| Ball Valve, β = 1 | 300 | 0.017 | 3.5 |

| Butterfly Valve | 1000 | 0.690 | 4.9 |

| Swing Check Valve | 1500 | 0.460 | 4.0 |

| Lift Check Valve | 2000 | 2.850 | 3.8 |

| 2K Method | |||

| Diaphragm Valve, Dam Type | 1000 | 2.0 | |

| Tilting Disk Check Valve | 1000 | 0.5 | |

Square Reduction

For Re1 < 2500

K = (1.2 + 160/Re1)[(D1/D2)4 - 1]For Re1 > 2500

K = (0.6 + 0.48f1)(D1/D2)²[(D1/D2)² - 1]Re1 is upstream Reynold's number at D1 and f1 is friction factor at this Reynold's number.

Tapered Reduction

For θ < 45°, multiply K from square reduction by 1.6 sin(θ/2).

For θ > 45°, multiply K from square reduction by sin(θ/2)0.5.

Rounded Pipe Reduction

K = (0.1 + 50/Re1)[(D1/D2)4 - 1]Square Expansion

For Re1 < 4000

K = 2[1 - (D1/D2)4]For Re1 > 4000

K = (1 + 0.8f1)[1 - (D1/D2)²]²Re>Re1 is upstream Reynold's number at D1 and f1 is friction factor at this Reynold's number.

Tapered Expansion

For θ < 45° multiply K for square expansion by 2.6 sin(θ/2).

For θ > 45° use K for square expansion.

Rounded Pipe Expansion

Use K for square expansion.

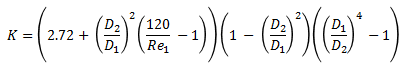

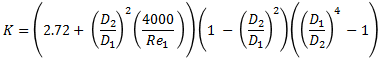

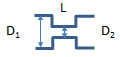

Thin Sharp Orifice

For Re1 > 2500

For Re1 > 2500

Thick Orifice

For L/D2 > 5, use equations for square reduction and a square expansion.

For L/D2 < 5, multiply K for a thin sharp orifice by

0.584 + (0.0936 / ( (L/D2)1.5 + 0.225))Pipe Entrances

Flush/ Square Edged

K = 0.5

Rounded

| r/D | K |

|---|---|

| 0.02 | 0.28 |

| 0.04 | 0.24 |

| 0.06 | 0.15 |

| 0.10 | 0.09 |

| 0.15+ | 0.04 |

Inward Projecting (Borda)

K = 0.78

Chamfered

K = 0.25

Pipe Exits

K = 1.0 for all geometries

Resources

- Web based calculation available at checalc.com

- Spreadsheet for Pipe Fitting Losses

References

- An article on Pressure Loss from fittings 3K method at Neutrium.net

- An article on Pressure Loss Expansion & Reduction at Neutrium.net

- Chemical Engineering Fluid Mechanics, Ron Darby, 2nd Edition