Compressible Fluid Flow

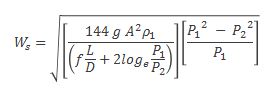

Flow of compressible fluid like vapors and gases through pipe is affected by changing conditions of pressure, temperature and physical properties. General relation for evaluating such flow is given by following equation in English units.

where, f is Darcy's friction factor, L is pipe length (ft), D is pipe diameter (ft), ρ is fluid density (lb/ft³), A is pipe cross-sectional area (ft²), g is constant 32.174 ft/sec², P is pressure in psi and Ws is gas flow (lbm/sec). Subscript 1 denotes conditions at pipe inlet and 2 denotes at pipe outlet.

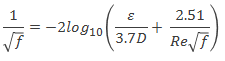

Friction factor is determined based on Reynolds's number (Re).

Re = D V ρ / μwhere, μ is fluid viscosity.

For Re < 2100, flow is laminar and friction factor is calculated as following.

f = 64 / ReFor Re > 4000, flow is turbulent and friction factor is obtained by solving Colebrook White equation.

Sonic Velocity

The maximum possible velocity of a compressible fluid in a pipe is called sonic velocity.

Vs = 68.1 [ (Cp/Cv) P/ρ]0.5where, Cp/Cv is gas specific heat ratio, P is pressure in psi, ρ is density in lb/ft³ and Vs is sonic velocity in feet/sec.

Mach Number

The Mach number is the velocity of the gas divided by the sonic velocity in gas.

Ma = V/ Vswhere V is gas velocity in pipe and Vs is the sonic velocity.

Erosional Velocity

Erosional velocity is maximum allowable gas velocity in a pipeline, as gas velocity increases, vibration and noise increases. Erosional velocity can be estimated as following.

Vmax = 100 / ρ0.5where ρ is gas density in lb/ft³ and Vmax is erosional velocity in ft/sec.

Resources

- Web based calculation available at checalc.com

- Spreadsheet for Compressible Fluid Flow

References

- Pressure drop in pipeline at PetroWiki

- Ludwig's Applied Process Design, Volume 1, 4th Edition