Bingham Plastic Fluid

Bingham plastic is a material that behaves as rigid body at low stresses but flows as a viscous fluid at high stress. This behaviour is exhibited by slurries, suspensions of solids in liquids, paints, emulsions, foams, etc.

Bingham model is described by following relation.

τ = τo + μp γwhere, τ is shear stress, γ is shear rate, τo is called minimum yield stress and μp is called plastic viscosity.

Reynolds number for Bingham plastic fluid is defined as

Re = D V ρ / μpwhere, D is pipe inside diameter, V is fluid velocity and ρ is fluid density.

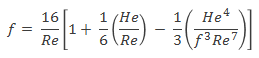

For Laminar flow, friction factor is provided by Buckingham Reiner equation.

where, He is Hedstrom number and is calculated as

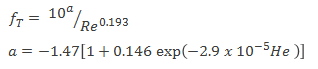

He = D²ρτo / μp²For turbulent flow, an empirical relationship was developed by Darby and Melson.

The friction factor for a Bingham plastic can be calculated for any Reynolds number from the equation.

f = ( fLm + fTm ) 1/mwhere, fL is laminar flow friction factor and fT is turbulent flow friction factor. Factor m is calculated from following equation.

m = 1.7 + 40,000 / RePressure drop is calculated as

ΔP = 2fρV² (L'/D)L' = L + Lewhere, L is the pipe length and Le is equivalent length due to loss in pipe fittings and is calculated as

Le = kD / 4fResources

- Web based calculation available at checalc.com

- Spreadsheet for Bingham Plastic Fluid

References

- Bingham plastic at Wikipedia

- Fluid friction at Petrowiki

- Chemical Engineering Fluid Mechanics, Ron Darby, 2nd Edition